Then & Now

From ancient times from the far east of the world to the present time cheese has been a great source of nutrition. Widmer’s Cheese Cellars has been caring on the tradition past down from generation to generation.

The History of Cheese Making

Cheese is a nutritious milk product that has been one of man’s most important foods for thousands of years. The United States and France rank as the leading cheese-producing countries. Wisconsin is the leading cheese making state. Wisconsin Cheese comes in about 350 varieties and in many different sizes and shapes. There are literally several thousands of varieties world wide.

Legend has it that thousands of years ago, an Arabian trader was crossing a rough, mountainous section of Asia. After many hours of torturous climbing under a hot sun, the weary traveler paused to refresh himself with dried dates and goat’s milk. As he lifted the canteen, made from a dried sheep’s stomach, to his lips, only a thin, watery liquid trickled out. Curious, the Arab cut the skin to see what happened to the rich, goat’s milk he had originally poured into it. To his surprise, he found a soft mass of curd. The rennet in the partially-dried sheep’s stomach had curdled the milk, and the result was cheese.

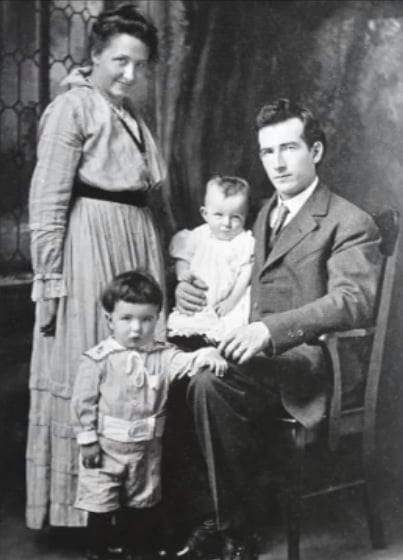

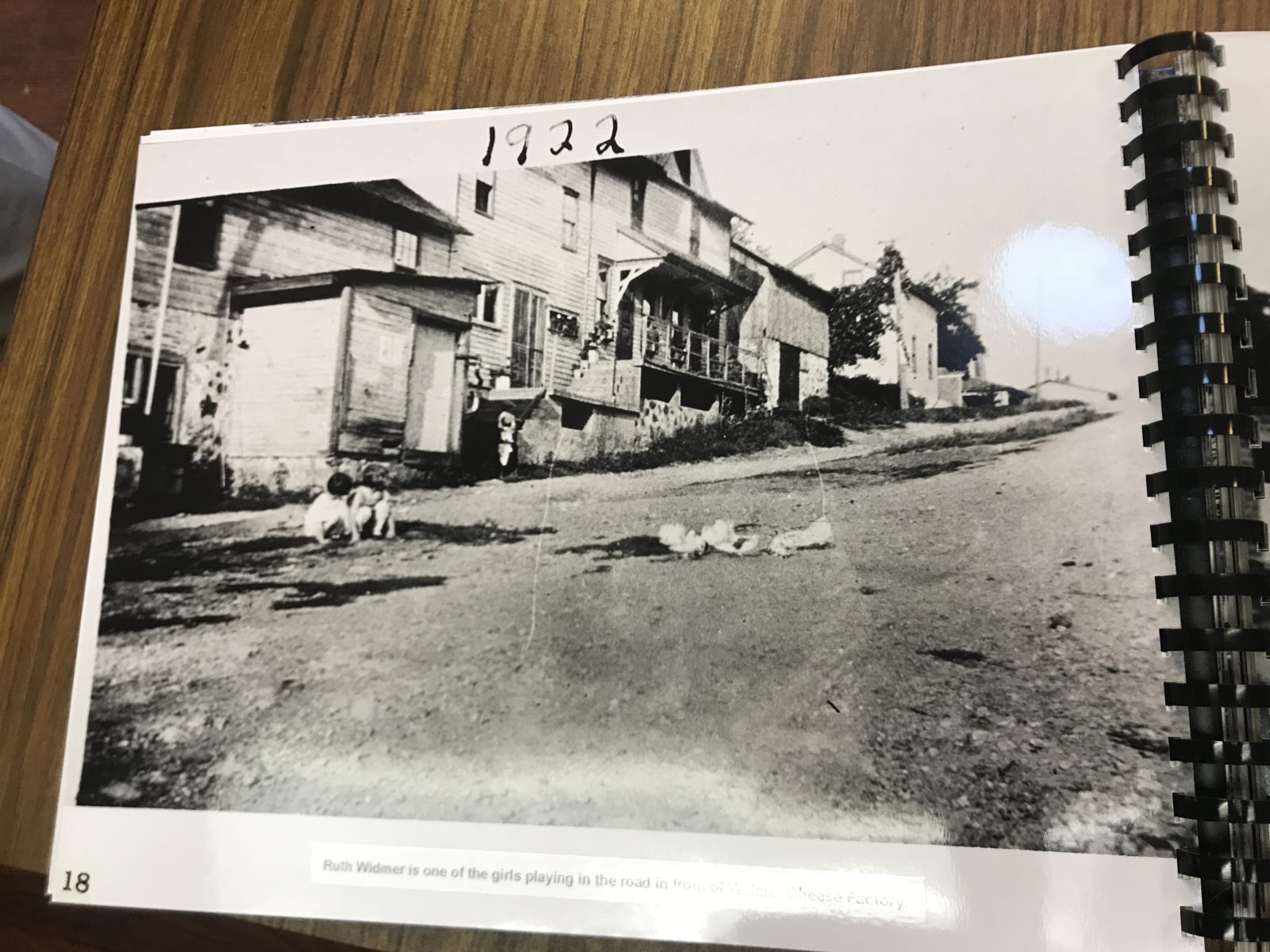

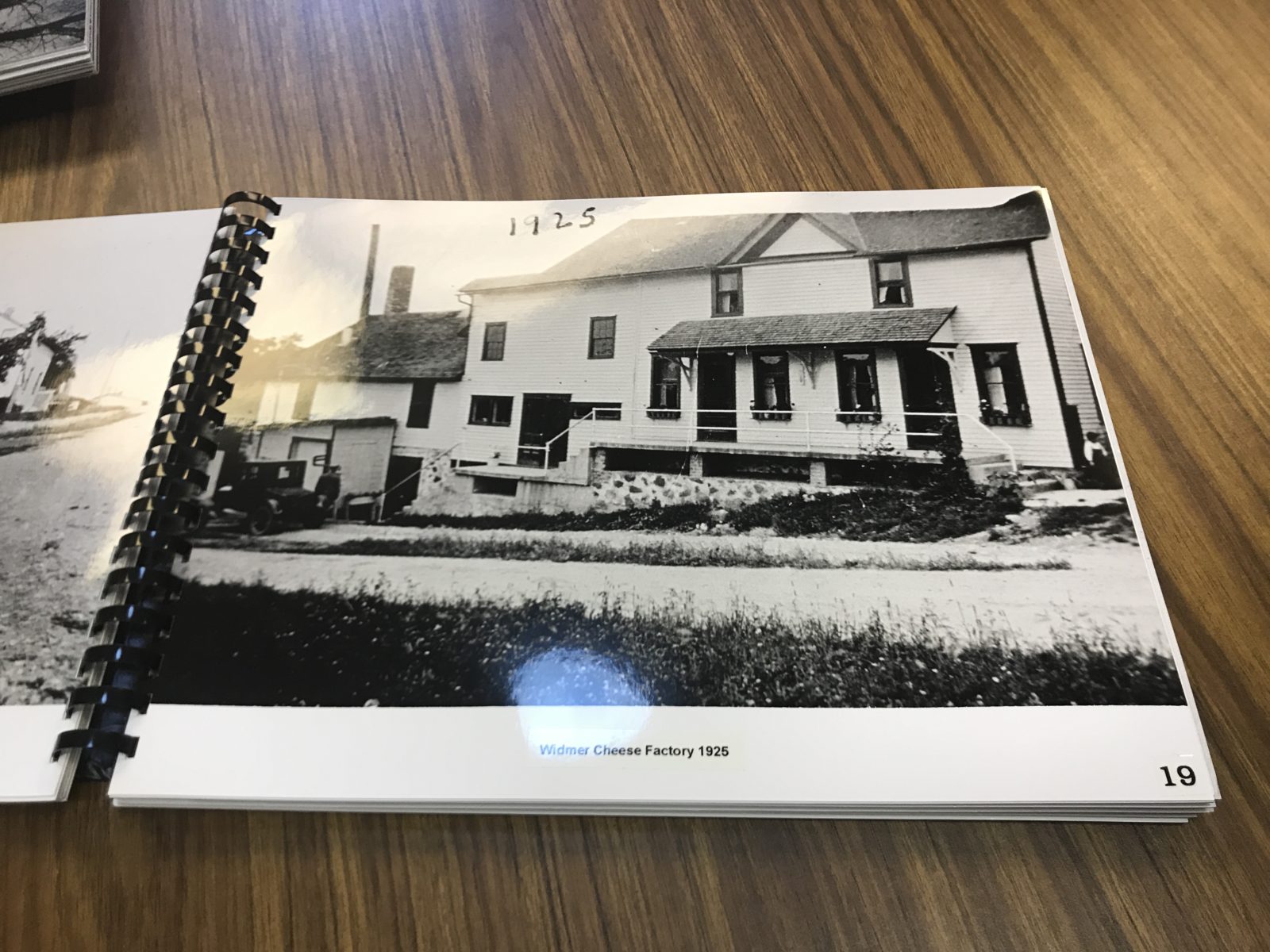

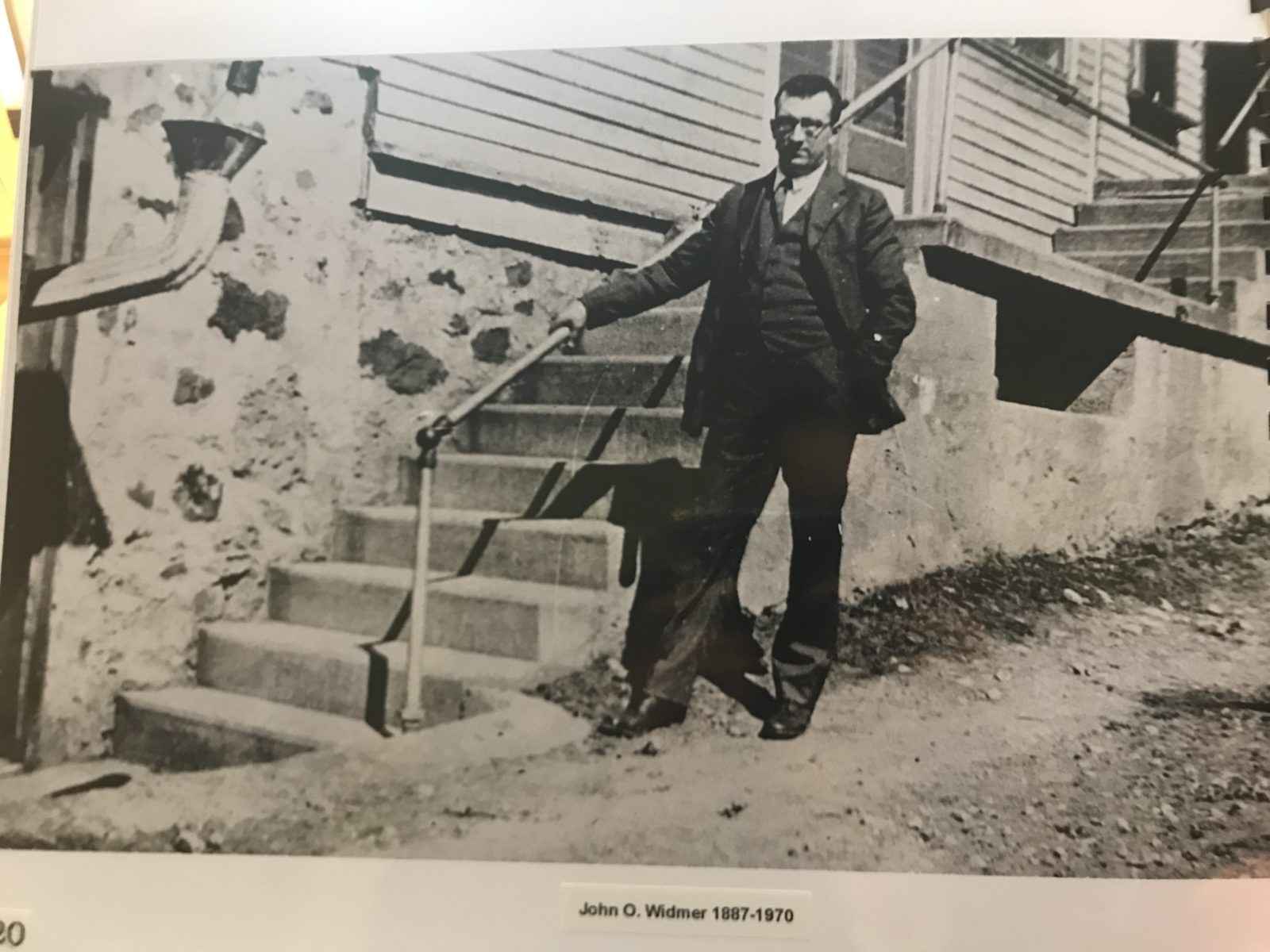

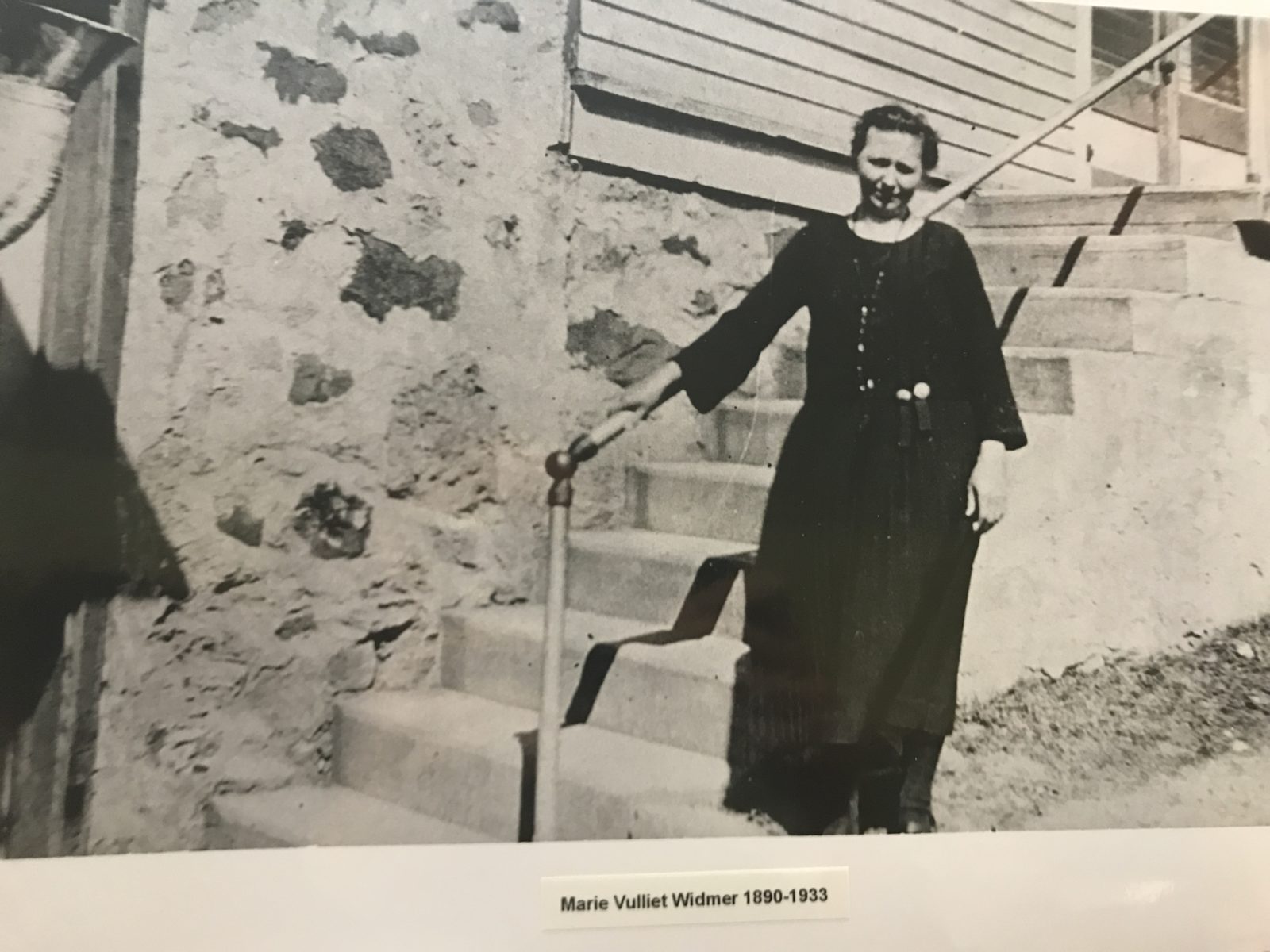

The story of Widmer’s Cheese begins over 80 years ago, when our founder, John O. Widmer, left Switzerland to come to America. He choose to settle in one of the most famous cheese producing regions of the world, Dodge County Wisconsin. As did many Swiss immigrants, John O. Widmer became a cheese maker. He worked in various cheese factories as an apprentice before settling in Theresa Wisconsin in 1922.

His theory was quality first, and he consistently strove to produce a better product. He passed on his methods to his three sons John, Ralph and Jim who have since retired, and passed on the family business and tradition to Joe Widmer.

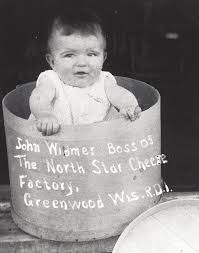

Embracing the manufacturing techniques which have been handed down through generations of cheese makers, Widmer’s Cheese Cellars offers a Wisconsin original, Wisconsin Brick cheese, a cheese of unsurpassed distinction. John J. Widmer as a baby in a Cheddar Box. Much like a limited edition book or lithograph, Widmer Brick is hand-crafted in small batches to ensure quality. Brick’s earthy, sweet flavor and its slice ability make it not only delicious, but easy to use as a table cheese or as an ingredient.

Methods for making cheese vary according to the type of cheese, but the basic manufacturing process for all cheese is essentially the same as the one we use to make Widmer Brick. The fresh, sweet milk is picked up at nearby farms and brought to the cheese factory via bulk truck. The milk is pasteurized, which means it’s heated to 162 degrees and cooled down to 90 degrees. It is then pumped into stainless steel vats.

A “starter” culture of lactic acid bacteria is added to the milk and automatic paddles stir the mixture to distribute the bacteria throughout the milk. In thirty minutes, rennet, a substance obtained from the lining of a calf’s stomach, is added. This acts as a curdling agent. The fluid milk is now allowed to “set” for thirty minutes, which then coagulates into a soft, semi-solid mass called curd.

Two large wire knives are used to cut the curd into 1/4-inch cubes. Again the paddles stir the cubed curd and whey. The whey is the liquid portion. The curds and whey are then cooked for about 40 minutes, to develop the proper degree of firmness and acidity. The whey is gradually drained from the vat, and the curds are then put into stainless steel hoops (forms) on drainage tables.

Covers are placed in the hoops and a brick on top provides the weight to press the curds into approximately 3 pound pieces.

Generally speaking one pound of cheese can be obtained from 10 pounds of milk. Each hoop is turned three times in the course of the day, and the following morning, the cheeses are placed in a strong salt solution (brine) where they are allowed to remain for 12 hours. After being removed from the brine, the finished bricks are put on fiberglass shelves in the curing room.

The temperature of the curing room is kept at 70 degrees and the cheese remains in there for about one week. In this week, each cheese is washed and turned twice. The washing helps develop a nice rind and is necessary to the curing process

The Foil Pack Brick is kept wetter than the Vac Pak and a smear is developed on the rind. The Foil Pak cures rapidly and develops into the old-fashioned Aged Brick Cheese. The Vac Pak is kept drier in the curing room and is eventually packaged, the cheese is put into 40-degree cold-storage rooms and is ready to be sold in about two weeks. The cheese is sent to all fifty states, but the bulk of the output is sold in Wisconsin.

Traditional Cheddar production photographed at Widmer Cheese in 19– for Encyclopedia Britannica. Widmer’s Cheddar production has changed little: today, we still use the same time honored techniques.